Boiler Accessories

Welcome to Sanvi Trading and Consultancy, your reliable source for premium boiler accessories in Nepal. We specialize in providing a wide range of high-quality boiler parts and accessories, including safety valves, water pumps, pressure gauges, and control systems designed to improve the efficiency and performance of your boiler systems. Whether you are managing an industrial facility, commercial building, or residential property, our durable and energy-efficient boiler components ensure smooth operation and safety. Explore our comprehensive range today and optimize your boiler system’s efficiency.

Thermodynamic Steam Trap

A thermodynamic steam trap is designed to remove condensate, air, and non-condensable gases from steam lines while preventing steam leakage. It operates on the difference in velocity between condensate and steam, making it highly efficient under varying pressure and temperature conditions. Known for its compact design and all-stainless-steel construction, it can withstand high pressure and water hammer. This trap is widely used in power plants, chemical plants, and industrial heating systems where durability and low maintenance are required. Its rugged build makes it suitable for outdoor and exposed locations.

Temperature Gauge

A temperature gauge is an essential instrument for monitoring the temperature of steam, hot water, or thermal fluids within a boiler system. It provides accurate readings, enabling operators to maintain safe and efficient operating conditions. Mechanical dial gauges are durable and easy to read, while digital versions offer higher accuracy and remote monitoring. By displaying real-time data, temperature gauges help prevent overheating, energy loss, and equipment damage. They are used across industries where temperature precision is crucial.

Temperature Sensor

A temperature sensor measures variations in heat levels and converts them into electrical signals for monitoring and control. Common types include thermocouples, RTDs, and digital sensors, each suitable for specific applications. In boilers, these sensors are integrated into automation systems to regulate combustion, water feed, and steam output.

Their real-time data ensures safety, energy efficiency, and compliance with industrial standards. With their ability to detect even small changes in temperature, they are indispensable in modern boiler systems.

Steam Control Valve

The steam control valve regulates the flow and pressure of steam to downstream equipment and processes. By maintaining steady pressure and flow, it ensures consistent heating and protects sensitive machinery from fluctuations. Control valves can be manual or automated, with actuators for precise adjustment. They play a crucial role in process industries such as food, textile, and pharmaceuticals, where steam quality affects production. Proper steam control reduces energy wastage, enhances efficiency, and ensures long equipment life.

Safety Valve

A safety valve is a critical protective device installed on boilers to release excess pressure automatically when it exceeds safe limits. Its quick response prevents catastrophic failures such as explosions, making it mandatory by safety standards worldwide. These valves are carefully calibrated and sealed to prevent tampering. Built from high-quality materials, safety valves withstand extreme temperature and pressure cycles. Their reliable performance makes them one of the most important accessories in any boiler system.

Pressure Transmitter

A pressure transmitter continuously monitors boiler pressure and converts it into standardized signals, such as 4–20 mA, for integration with control systems. This allows remote supervision and automation, helping maintain precise operational limits. Compact and robust, pressure transmitters are designed to perform under harsh industrial conditions. They ensure early detection of pressure variations, preventing potential breakdowns and unsafe operations. By linking with SCADA or PLC systems, they support smart boiler management.

Pressure Switch

The pressure switch is a mechanical or electronic device that activates or deactivates electrical circuits based on preset pressure levels. In boiler systems, it controls burner operation, pumps, or alarms depending on conditions. Simple yet reliable, it provides a safety interlock to prevent accidents from overpressure or underpressure. Adjustable and versatile, pressure switches can be used in both high- and low-pressure applications. Their rugged design makes them highly dependable for continuous boiler operations.

Pressure Reducing Valve

A pressure reducing valve automatically reduces high inlet steam or water pressure to a steady, lower outlet pressure. This protects downstream equipment from damage and ensures safe operation. It maintains constant pressure regardless of load variations, making it critical in distribution systems. The valve is compact, durable, and requires minimal maintenance, offering both safety and energy efficiency. Commonly installed in commercial and industrial setups, it ensures consistent steam supply without manual intervention.

Oil Burner (17 KW–13255 Kw)

The oil burner is a combustion unit that delivers controlled burning of liquid fuels to generate heat for boilers. With a capacity range of 17 kW to 13,255 kW, it is suitable for small-scale industrial plants to large utility boilers. Burners are designed for complete fuel-air mixing, ensuring clean combustion, reduced emissions, and high efficiency. Equipped with ignition systems and flame monitoring, they provide safe, reliable operation. Oil burners are engineered for durability, easy maintenance, and adaptability to different fuel grades.

Magnetic Switch

A magnetic switch operates through magnetic fields to open or close an electrical circuit without direct physical contact. In boilers, it is commonly used for burner control, flame monitoring, and safety interlocks. Its design ensures minimal wear, reducing the need for frequent maintenance. Magnetic switches are highly responsive, reliable, and resistant to dust and moisture. They provide safe and precise control in automated boiler systems.

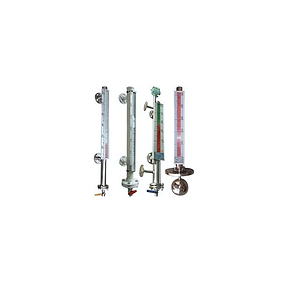

Gauge Glass

Gauge glass provides a direct visual indication of water level inside the boiler. It is a transparent tube mounted on the boiler drum and fitted with valves for isolation and blowdown. This simple yet critical accessory prevents accidents caused by low or high water levels. Operators can easily monitor and adjust water feed using gauge glasses. Available in tubular, reflex, and transparent types, they are tailored for different industrial applications

Hot Water Generator Coil

The hot water generator coil is a heat-exchanger element that transfers heat from steam, hot gases, or thermal oil to water. Its design ensures quick heating with minimal energy loss, making it highly efficient. Coils are built from high-grade steel or copper to withstand corrosion and high pressure. They are widely used in industries requiring continuous hot water, such as food processing, textiles, and pharmaceuticals. With compact design and high thermal conductivity, these coils deliver long service life and performance.

H Type Ignition Electrode

The H-type ignition electrode produces a powerful electric spark to ignite fuel in oil or gas burners. Its unique H-shaped configuration enhances arc stability and ensures quick, reliable ignition. Made from heat-resistant alloys, it withstands repeated ignition cycles and high operating temperatures. This electrode is essential for maintaining consistent burner performance and minimizing startup failures. It ensures safety, efficiency, and smooth boiler operation.

Hot Water Boiling C

The hot water boiling chamber is the central section of the boiler where water is heated and converted into steam or hot water. Constructed from high-grade steel, it is designed to withstand extreme pressure and high temperatures. Its insulated design minimizes heat loss, ensuring maximum efficiency. Proper circulation within the chamber promotes even heating and prevents scaling. This chamber plays a vital role in ensuring safety, energy efficiency, and long service life of the boiler.

Gauge Valve Set

The gauge valve set is installed alongside the gauge glass to control and isolate water flow for level measurement. It consists of a pair of valves—one at the top and one at the bottom allowing safe operation, maintenance, and blowdown of the gauge glass. This prevents boiler shutdown during glass replacement or servicing. The set enhances operator safety by preventing direct exposure to hot steam and water. Built from durable materials, it ensures leak-free and long-lasting performance

Metallic Gasket

A metallic gasket provides a tight, durable seal between two flanged surfaces in high-pressure boiler systems. Designed to withstand extreme heat, steam, and chemical exposure, it prevents leaks and ensures operational safety. Common types include spiral wound, ring-type joints, and corrugated gaskets. These are widely used in steam lines, pressure vessels, and high-temperature applications. Their long lifespan reduces maintenance costs and downtime in boiler operations.

Float Valve

A float valve automatically regulates water levels in boiler tanks through a buoyant float mechanism. When the water level drops, the float lowers, opening the valve to allow water in. As the level rises, the valve closes to stop inflow, preventing overflow. Simple, reliable, and mechanical, float valves require little maintenance. They ensure uninterrupted water supply, reducing the risk of boiler damage from low water levels.

Float Rod Mobrey

The Mobrey float rod is a float-operated level control system used in boilers to monitor water levels accurately. It sends mechanical or electrical signals to feedwater pumps, alarms, or burner controls. This ensures automatic water level regulation and protection against low-water conditions, which can cause overheating and tube damage. Known for reliability, it is widely used in power and process industries. Its rugged design guarantees long service life with minimal maintenance.

Cold Water Flow Meter

The cold water flow meter measures the volume and rate of water entering the boiler. It provides accurate data for monitoring consumption, detecting leaks, and optimizing water usage. Available in mechanical, turbine, or digital types, these meters suit various industrial needs. By tracking water input, operators can maintain efficiency and detect anomalies early. This accessory supports cost control and reliable boiler operation.

Flame Rod

The flame rod is a safety device that detects the presence of flame in burners using ionization technology. It ensures that fuel is only supplied when a flame is established, preventing dangerous unburned fuel buildup. If flame failure occurs, the rod signals immediate fuel cut-off. Flame rods are heat-resistant, durable, and crucial for safe combustion monitoring. They are widely used in modern oil and gas burners for reliable boiler protection.

Flanges & Gaskets

Flanges and gaskets are essential components for connecting and sealing joints in boiler pipelines. Flanges provide a strong mechanical connection between pipes, valves, and equipment, while gaskets create a tight seal to prevent leaks under high pressure and temperature. They ensure safe fluid transfer, reduce energy losses, and allow for easy maintenance or replacement of boiler parts.

EPDM Tyton Gasket

The EPDM Tyton gasket is a specialized sealing component made from Ethylene Propylene Diene Monomer (EPDM) rubber. It is resistant to heat, steam, and chemical corrosion, making it ideal for boiler systems. Its elasticity ensures a secure seal even under pressure fluctuations, preventing leaks and improving system reliability. Widely used in water and steam lines, it provides long-lasting performance in demanding environments.

Ceramic Blanket

A ceramic blanket is a high-temperature insulation material used in boilers and furnaces. Lightweight yet durable, it provides excellent thermal resistance, minimizing heat loss and improving energy efficiency. It withstands extreme operating conditions, reduces surface heat, and enhances operator safety. Commonly applied around boiler chambers and piping, ceramic blankets extend equipment life by protecting against heat damage.

Electrode

Electrodes in boilers are crucial for ignition and flame detection. They generate the initial spark needed to ignite the fuel-air mixture and ensure continuous flame monitoring during operation. Built from heat-resistant materials, electrodes withstand high combustion temperatures while delivering reliable performance. Their role in safe startup and operation makes them a critical part of burner control systems.

Boiler Nozzle

A boiler nozzle regulates the spray of fuel into the combustion chamber, ensuring proper atomization for efficient burning. Designed for precision, it delivers the correct fuel flow rate and spray angle, supporting complete combustion with minimal emissions. High-quality nozzles enhance energy efficiency, reduce fuel wastage, and maintain stable flame conditions, making them vital for consistent boiler performance.